Button valve working principle and the first difficult press analysis

The main function of the pressure button valve is to avoid impact damage to the pressure gauge when the pipeline pressure changes drastically. At the same time, At the same time, the pressure gauge can be disassembled online to avoid the loss caused by the stop line and facilitate after-sales maintenance.

Its main components are composed of valve bonnet, main shaft, "O"type seal ring, spring and valve body. The structure is as follows:

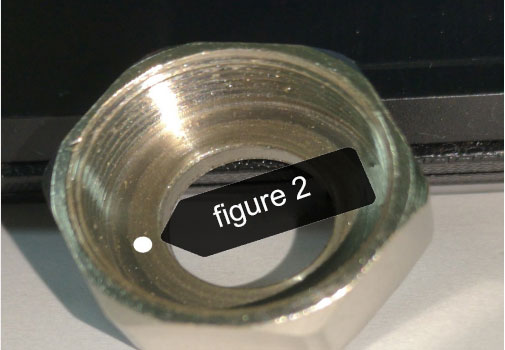

When working, press the main shaft to overcome the resistance of the spring, so that the main shaft moves downwards. The gas flows into the valve cavity from the upper small hole at the inlet, and flows out through the small hole at the outlet through the main shaft buffer to reach the pressure gauge. After the measurement is finished, the main shaft moves upward under the action of the spring force to reach the top end, and the lower seal ring of the main shaft is above the small hole at the outlet of the valve body to block the gas.The sealing of the button valve is mainly ensured by three O-rings. In order to ensure a smoother pressure and reduce the friction between the O-ring and the valve cavity and better sealing, the inside of the valve cavity is usually filled with lubricating oil. If the rolling action is not performed for a long time, the contact between the main shaft and the bonnet (figure 1 and figure 2) is in close contact under the pressure of the spring, and at the same time, because both surfaces have the presence of liquid lubricating oil, the filling of the liquid lubricating oil and Under the combined action of the spring pressure, a partial vacuum state is formed, therefore, under the dual action of the atmospheric pressure and the mutual attraction of the liquid molecules, it is difficult to perform the first opening and pressing.