Natural gas burner operating conditions and gas solenoid valve

Natural gas burner operating conditions and gas solenoid valve

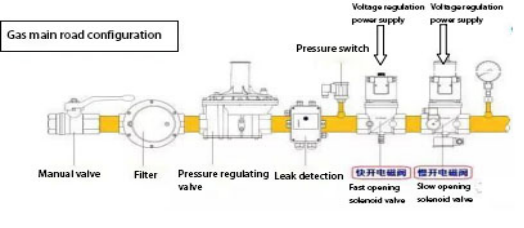

A natural gas burner is a system that can generate ignition heat by inputting natural gas and power. The system includes many instruments such as pressure reducing valves, filters, regulators and other control devices. The gas solenoid valve acts as a switch here to achieve the on/off of the natural gas pipeline.

Gas solenoid valves are also divided into many types. Here,taking a fast opening solenoid valve for an example. The basic function of the fast opening gas solenoid valve is that it opens when the power is on and shuts off when the power is off.It is structurally divided into two parts, the mechanical action part of the valve body and the coil part. When the power is applied, the magnetic force generated by the coil drives the core of the valve body to open the valve . When the power is off, the electromagnetic force disappears, and the iron core closes the valve by the action of the spring.

Normal working conditions, gas solenoid valve switching life can reach more than 500,000 times

A variety of equipment is generally installed in the natural gas burner to ensure the normal operation of the system, the filter can filter impurities to clean the gas in the pipeline, the pressure reducing valve can adjust the gas pressure and a voltage regulator needs to be installed for the external power supply and so on . The use of these devices can, to a certain extent, give the combustion system a good working condition.

一、the regulated power supply and solenoid valve

The on/off function of the solenoid valve is to achieve mechanical movement under the action of electromagnetic force.The magnitude of the electromagnetic force and the normal life of the electronic components are related to the voltage and current.Therefore, the power parameters within the standard range can guarantee the basic function and normal life of the solenoid valve.

The operating voltage of the burner is generally 220V (the national industry standard allows 220V fluctuation range of 187V-242V).The voltage fluctuates greatly due to different geographical regions and different time zones in China, and sometimes even exceeds the upper and lower limits of voltage. The voltage is too low and the voltage is too high, that will greatly affect the life and function of the solenoid valve.

The operation of the solenoid valve needs power supply. The factory will install a power regulator to adjust the voltage to a reasonable interval and then supply power to the instrument on the burner.

The effect of ultra-low voltage on the solenoid valve: When the voltage is low enough to exceed the lower limit of 187V, the magnetic force of coil is too small , which may cause the valve failing to open, affecting the performance of the solenoid valve or directly causing functional failure.

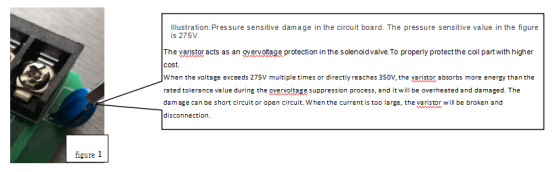

The effect of ultra-high voltage on the solenoid valve: When the voltage is above 220V for a long time, even exceeding the upper limit of 253V, the coil life will be affected due to over-hot. The varistor life will be affected if the voltage is above 275V multiple times or frequently,which Causes a pressure-sensitive burst (Fig. 3) or burns black when the condition is severe.

Figure 1 shows the effect of abnormally high voltage (multiple times above 275V or 350V instantaneously) on the solenoid valve: pressure sensitive damage in the board (other electronic components will also be damaged due to excessive current).

2.The effect of higher voltage (245V-275V) on the solenoid valve: shorten the life of the coil until the coil burns out.The coil generates a magnetic force due to energization. The higher the voltage, the greater the electromagnetic force and the higher the coil temperature. When the voltage is stable at 220V, the coil temperature is generally about 65 degrees (the specific temperature is related to the ambient temperature). When the voltage exceeds 220V, the electromagnetic force increases and the coil temperature rises. The basic requirement for solenoid valve performance is to ensure the normal function of the solenoid valve at the extreme low voltage (187V).Since the electromagnetic force is sufficient at the extreme low voltage, it is functionally unnecessary to increase the voltage to increase the electromagnetic force. Therefore, the ultra-high voltage is harmful to the solenoid valve, and as the voltage increases, the coil temperature rises. A high voltage state for a long time affects the life of the coil until the coil burns out.

When all of the above occurs, you should consider re-opting the power regulator. At the same time, it should be noted that the maximum voltage after voltage regulation should not be too high, otherwise it will lose the meaning of voltage regulation.

In addition,to install a relay on the burner can provide a set of protection measures for electrical devices such as solenoid valves .

二、The filter and solenoid valve:

Install a suitable filter to clean the gas, reduce the possibility of impurities, especially magnetic impurities, entering the interior of the solenoid valve, which can greatly reduce or eliminate the solenoid valve failure caused by foreign matter.

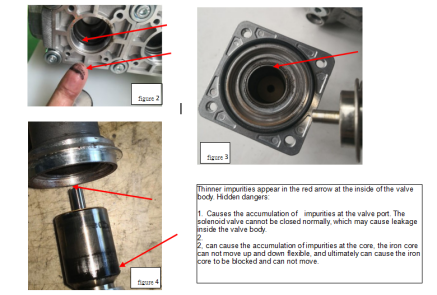

In actual use, if the filter is not installed or an inappropriate filter is installed (the number of meshes is too small), it is often the case that impurities enter the solenoid valve and the core is stuck.

1.Example: Pulverized coal exists in gas that results in the valve port cannot be closed and the action of the iron core is blocked, and impurities enter the inside of the valve body.

In the case of the above, it is recommended to replace the filter. At the same time, it is recommended to replace the special solenoid valve, which can greatly reduce the solenoid valve function damage caused by impurities.

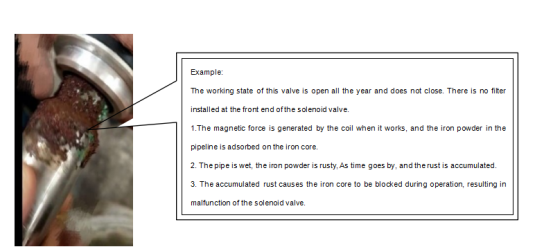

2.Example: If there are a large amount of water and iron power in the gas, rust will be formed and then be adsorbed onto the surface of the valve spool, causing incapability of closing up completely.

In the case of the above, it is recommended to install a filter or replace the filter.

三、Pressure reducing valve and solenoid valve:

The function of the pressure reducing valve is to adjust the pipe gas pressure to the working pressure range of the solenoid valve.

Normal pressure solenoid valve ignition pressure: 50 mbar (0.05Kg) is generally recommended. The pressure is different and the initial flame size is different.

Maximum working pressure of atmospheric solenoid valve: Maximum working pressure is 200 mbar-1000 mbar (0.2-1 kg).(The magnetic valve coil will have a magnetic loss when it is hot, so it is necessary to ensure that the solenoid valve works normally under the maximum working pressure when the coil is hot.In combination with the voltage,that is, when the coil is hot, it is also ensured that the solenoid valve can work normally at the maximum working pressure and the lowest voltage. This is the basic requirement for solenoid valve performance).

四、The effect of system grounding measures on the LED indicators in the solenoid valve:

Indicators are installed on the circuit section for some solenoid valves to visualize the working state of the solenoid valve.There are two types of indicators: xenon and LED. Both have advantages and disadvantages.LED lamps have a long life and can last up to 100,000 hours with proper current and voltage.

Although LED lamps have a long life,they are easily damaged if in improper use.Most of the reason is caused by static electricity.

Static electricity is the biggest enemy of LED lights. Under the action of static electricity, the life of LEDs will be seriously reduced, and even lead to damage. Careful users can find that sometimes the system has been powered off, but the indicator light is still slightly illuminated, which is the static electricity that causes the indicator light to illuminate.

Grounding for the burner is an effective measure to prevent static electricity damage. It can greatly reduce the damage of static electricity to the electronic components of the indicator light, and return the LED indicator to normal life.

The burner is an entirety. If any unit fails, it will cause the system to run abnormally. To ensure the normal operation of the system, we must first have a good working condition. The various units in the system are independent and interconnected, which provide a reliable guarantee for the overall function of the coal-fired machine.

Previous: Slow opening solenoid valve instruction

Previous: Slow opening solenoid valve instruction

Next: Happy Women's Day

Next: Happy Women's Day