The common faults in the use of solenoid valves

What do you know about the common faults in the use of solenoid valves?

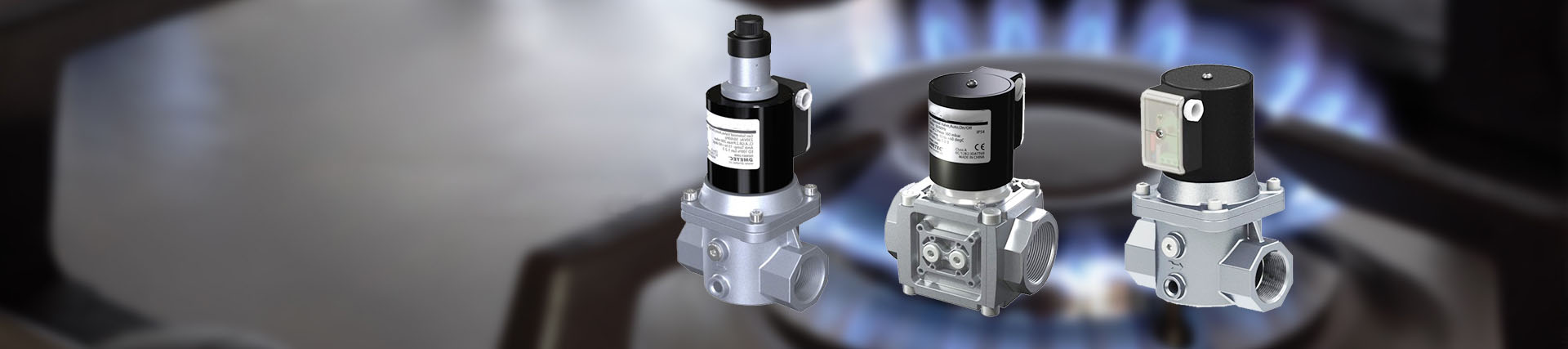

The SOLENOID VALVE is a safe emergency shut-off device for the gas pipeline. It can be connected to the gas leakage alarm system or to fire and other intelligent alarm control terminal modules to achieve on-site or remote automatic/manual emergency cut-off of the air source to ensure safe use of gas. It is an indispensable device on the field pipeline that uses gas equipment.

In the process of using the solenoid valve, the solenoid valve is not working properly due to the relationship between the supporting equipment of the pipeline environment.

The maintenance worker should first judge whether the solenoid valve itself is of quality problem and handle it so that the equipment can operate normally.

In actual use, we generally encounter the following situations,let us analyze it together, and teach you how to solve it!

Fault 1: The solenoid valve is not working properly? Why is this?

Cause analysis: The power supply is wrong. This is due to incorrect wiring, unreliable power supply, abnormal voltage, short circuit or open circuit during installation, resulting in the solenoid valve not working.

Handling suggestions: Check and correct the wiring error, and use it after the input power supply voltage is normal.

Fault 2: The solenoid valve port cannot be opened? (ie no ventilation, or incomplete ventilation)

Cause Analysis:

Cause (1) Voltage problem. The rated use voltage is 220V, and the allowable error range is ±15%. That is, it can be used normally in 187V-253V. There are two specific factors: ① When the power is low, sometimes the voltage will be too high, and the voltage in some areas may even be as high as 275V or above. In this case, the electronic component of the circuit board may be overload protected or directly burned out of the coil, resulting in the solenoid valve not working. In this case, the treatment suggestion is to carry out repairs. If this is the case in batches, it should be considered whether the voltage at the site is too high and timely repaired.

The electronic original has been damaged by the overload protection after the working voltage exceeds the specified voltage.

② When the peak voltage is used, sometimes the voltage will be low, and the voltage in some areas will even be lower than 185V. At this time, part of the solenoid valve will be affected by the voltage, and the electromagnetic force will be low, causing the valve port to not open normally. When the voltage returns to the normal standard range, the solenoid valve can resume normal operation. This kind of situation is easier to identify: if the voltage is stable, the solenoid valve can work normally after being energized again. It is recommended that no special treatment is required in this case.

Cause (2) Pipeline pressure problem. The working pressure of the solenoid valve should be within the allowable range. DN10-DN25, standard pressure is 360Mbar; DN65-DN100 and above, standard pressure is 200Mbar.

There are two factors that cause pipeline pressure problems:

①The solenoid valve is designed to work at a higher pressure than the standard pressure. However, if the air pressure in the pipe is too high and the standard pressure is exceeded, the valve port may not open properly.

②The regulator is damaged. The regulator does not regulate the air pressure in the pipeline, causing the pipeline pressure to be too high.

In case of pipeline pressure problems, it is recommended to diagnose and then process. To determine whether the solenoid valve has its own quality problem, just take the solenoid valve to the test within the allowable range of rated voltage and working pressure.

Fault 3: The solenoid valve cannot be closed?

Cause analysis: Gas impurity problem. The gas in the pipe contains impurities. After the impurities enter the core portion of the solenoid valve, the iron core is stuck and the valve port cannot be closed normally.

There are usually two factors: ① In the initial stage of pipeline use, there is more or less dust in the pipeline, it is easy to contain metal dust such as iron powder, and there is a certain magnetic force after the solenoid core is energized, and the metal impurities in the dust. It is easily absorbed inside the iron core. Cause the valve port to not close.

② The metal dust is adsorbed on the exposed part of the iron core for a long time, and there will be moist moisture in the pipeline. Over time, the metal dust will rust (not the iron core is rusted, but the metal dust attached to the surface is rusted). Cause the valve port to not close.

Handling suggestions: Clean up debris in the pipe and impurity in the spool. How to prevent such failures from occurring frequently? It is recommended to install a filter on the front end of the solenoid valve.

As the solenoid valve is opened for a long time, the damp dust in the pipe has rusted and accumulated on the iron core, causing the solenoid valve to not close properly.

Fault 4: The solenoid valve is normally closed, but the indicator is still flashing after turning off. What should I do?

Cause analysis: As long as there is current, the indicator light will be on. This situation indicates that the power supply has not been completely cut off, or there is still an induced current. After the controller's matching or quality problem causes the power supply to be cut off, the circuit board of the solenoid valve still has a weak power supply.

Handling recommendations: Check the quality of the pipe controller.

The processing method mentioned above, are you getting it?