You don’t really know this knowledge about gas solenoid valves.

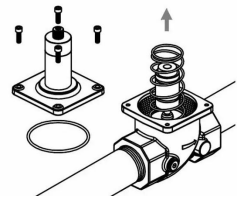

Just as its name implies,the solenoid valve uses the electromagnetic principle to generate magnetic force through the power supply coil,so that the lift stem moves upwards and cooperates with the internal spring mechanism to achieve on-off control. The solenoid valve is generally installed on gas or air pipe for the safety ,regulation and control of gas or air line in front of burner nozzle or other gas appliances.

Many people think that structure of solenoid valve is so simple and nothing else needs attention.But below, you don't really know all.

Ready? Let's go!

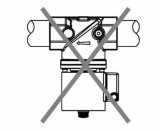

1.When installing, it is advisable to select a horizontal pipe section with less vibration.

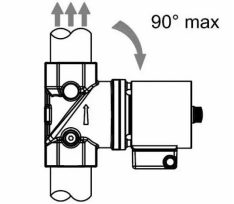

2.When the pipe is running vertically, the direction of the fluid should be from bottom to top, and such a fluid is more stable due to its own gravity flow.

3.In general, the solenoid can be rotated 360° freely.

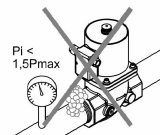

4.After installation, the air tightness test should be carried out, and the test pressure is 1.5 times the actual use pressure.

5.When selecting the solenoid valve,the pressure loss ΔP is generally not more than 1 KPa, and the pipe flow rate is generally not more than 15 m/s.

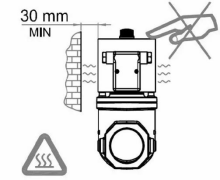

6.When the solenoid valve is energized for a long time, the coil heating is unavoidable. Different environments have different degrees of heat generation, and there is no difference in human body feeling when it exceeds 70 °C.

7.Do not install too close to the wall or other equipment, one for the convenience of operation, the second is to ensure the free flow of air around the solenoid valve, cooling the coil.

8.Maintain at least once every 1~2 years (the corrosive gas cycle should be shortened). Regular inspection and maintenance is the best way to reliably work and prolong the use of solenoid valves.

9.Due to the aging of the seal, for safety reasons, regardless of whether the solenoid valve is damaged, it should be replaced after 10 years of use.

The following conditions are the reasons that hinder the normal operation of the solenoid valve and shorten the life:

1.Medium changes in use.

2.Rusty inside the pipe.

3.Mixing tar and other impurities into the pipeline.

4.Impurities such as dust and dirt in the pipeline.