Features

* 24 hours continuous operation, hundreds of thousands of operating lifetimes

* IP54 protection level,Apply to site or cabinet installation

* Operation status display,fault information display and frame intensity display

* Remote or on-site reset

* Flame threshold can be set

* Meet the European EN298 standard

Application

FSC-1600 is a high-performance combustion safety controller.It has high detection sensitivity and reliable safety control performance.It has many functions ,such as ,fuction can be set, multiple failure indications, startup process and current flame threshold value display,which improves stability and controllability of operation.The light column shows the flame state to optimize the combustion efficiency, and is an ideal energy-saving product for reducing energy consumption and pollution.

FSC-1600 combustion controller applies to safety control of industry and commercial combustion system ,Auto-ignition and flame detection for a variety of gas fuels and liquid fuel burners.Wide range of applications, can be used in steel, machinery, metallurgy, glass, ceramics, chemicals and many other industries.

The main technical parameters

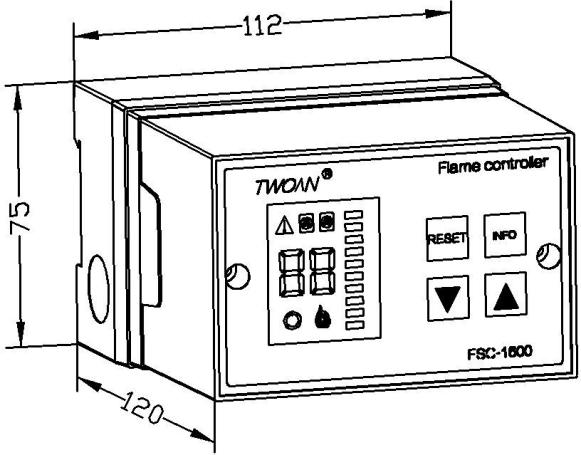

width*thickness*height:112*75*120mm

Input voltage:AC100~240V 50/60Hz

Lonic bar cable length:75m (the longest)

Flame threshold value: 1μA(Minimal)

Protection level:IP54

Environment temperature:-20℃ ~ +65℃

Environment humidity:< 95%

Operating life:>100 thousand times

Shell material:PC/ABS Black (Wiring base color ) Blue (shell color )

The maximum current of driving the gas valve:1A power factor:1

The maximum current of driving the igition transformer:2A power factor:0.2

The maximum current of the output terminal:2A ; AC Voltage:250v

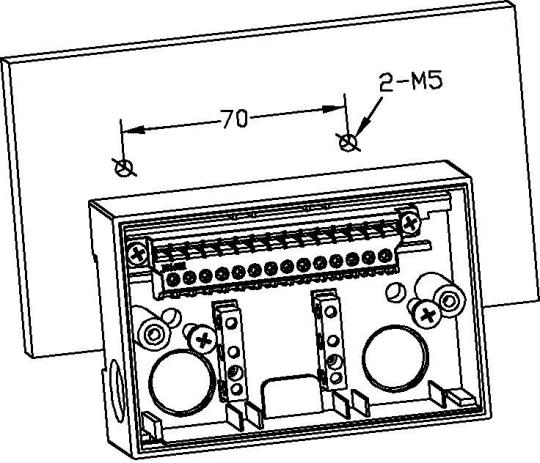

Dimensions:

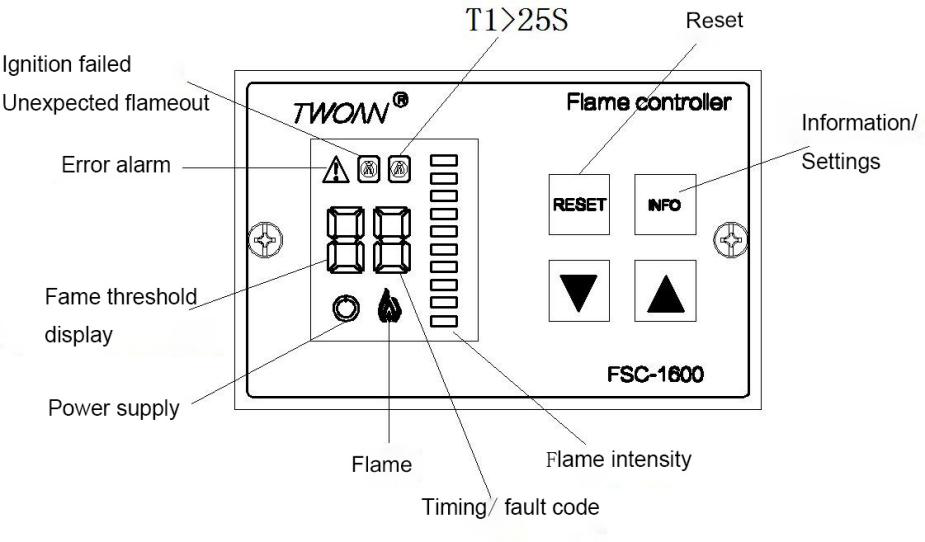

Panel description:

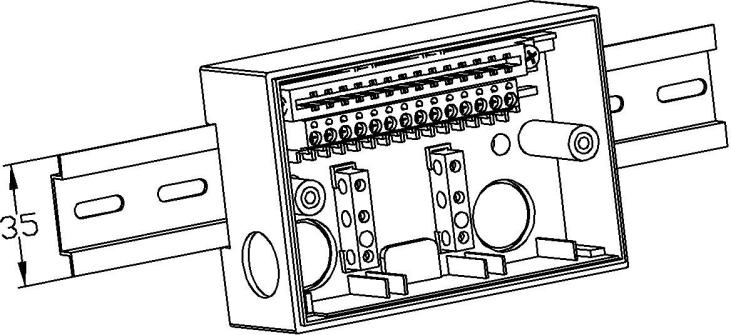

Installation diagram

Rail installation

Fixing plate installation

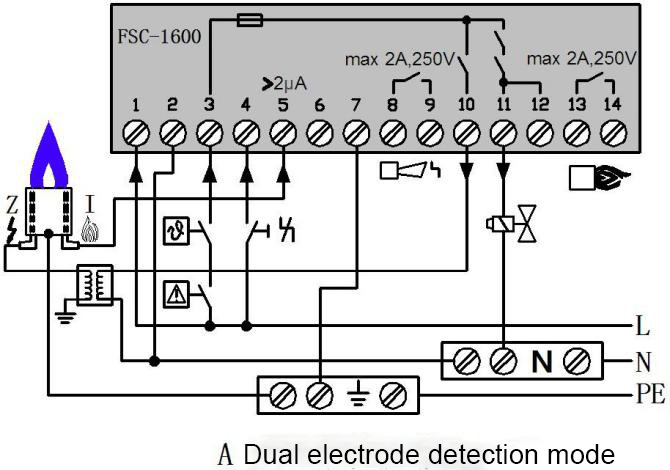

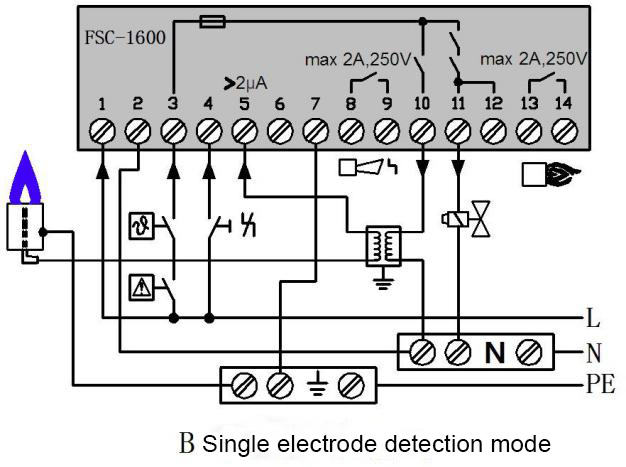

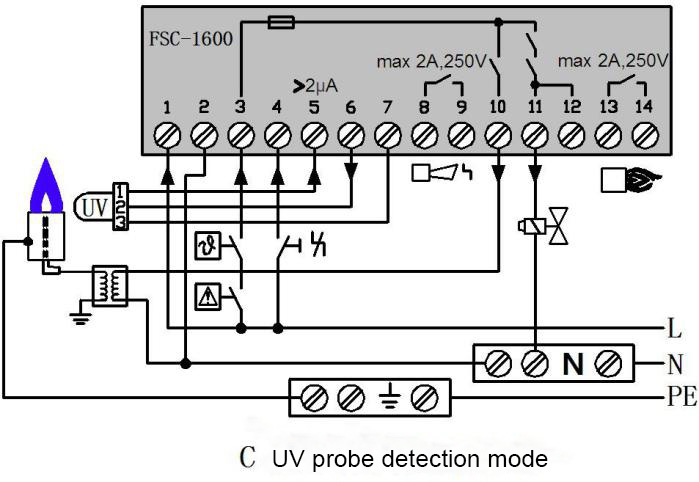

Wiring diagram

Key operation

RESET key:In the non-set status, the system can be started and stopped. In the setting status, the parameter setting can be switched.

INFO key:Use when entering setting status.

“▲” key and ▼key:Make parameter changes.

* Common setting parameters:

In the power-on status ,press the “▲ ” key an “INFO” key 3s at the same time to enter common parameters settings.

Press the “RESET”key to switch parameter symbol and parameter value.

Press the“▲”key and “ ▼” key to select the parameter to be set. selections are as follows:

* Parameter symbol:

No. | parameter | Defaults | Meanings |

1 | HL | 2 | Flame sensitivity settings: 1 ~ 10, the higher the value, the lower the sensitivity. |

2 | dH | 1 | Re-ignition settings:0 for no secondary ignition 1 for secondary ignition. |

3 | nP | 1 | Startup settings:1 for No panel operation requried at startup,0 for need to start from the panel operation |

4 | FA | 50 | Ignition time settings:30~60,0.1S for the unit |

5 | Fd | 0 | Setting of whether to detect the signal when ignition:0 for No detection,1 for detection |

6 | QU | -- | Press the“RESET”key to save and exit. |

If nP is set to 0, it is necessary to wait for 10 seconds before starting the second start process when entering the fault state.

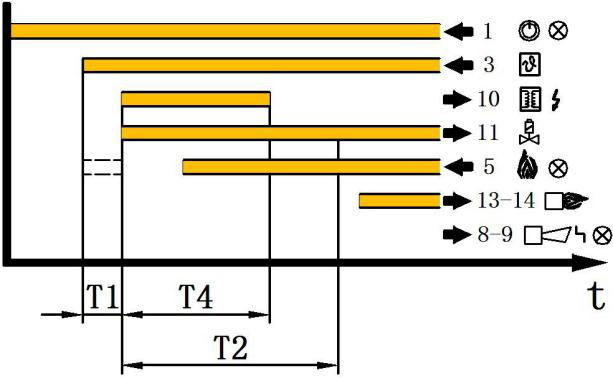

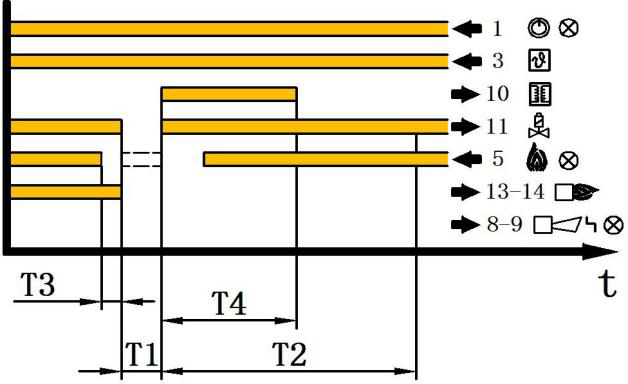

Working sequence

It mainly defines the running time sequence,time definition and fault status of controller.

1. Explanation of operating status displayed

(1)Power on, code "OF" stops

(2)Prepare, code "x 0", x shows the flame threshold value

(3)Flame Simulation (T1), code "x1"

(4)Ignition step (T2), code "x2"

(5)Normal operation, code "x3"

(6)Fault self-locking code, refer to the fault type table

2. Normal start

When receiving the starting signal, it performs a flame simulation test within the waiting time T1 after the controller is working., LED shows x1,if no flame is detected,the start-up safety time T2 LED shows x2 and it also supplies voltage to the gas valve and the ignition transformer at the same time,within T2s ,after receiving the flame signal,the signal output terminals 13 and 14 are closed,the burner starts normally and the LED shows the current running status code x3. The ten-digit LED shows the flame threshold value.

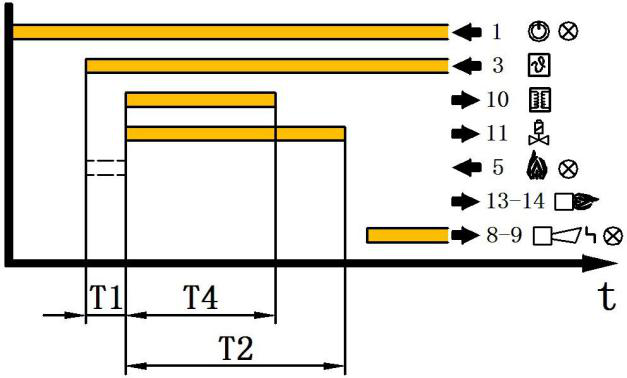

3.No flame signal during start-up process

After the burner is starting normally, if the controller does not detect the flame signal within the start safety time T2 ,the fault lock occurs,The fault signal output terminals 8 and 9 are closed.During the entire start-up safety time T2, the gas valve is open. The LED flashes to display fault code E2.

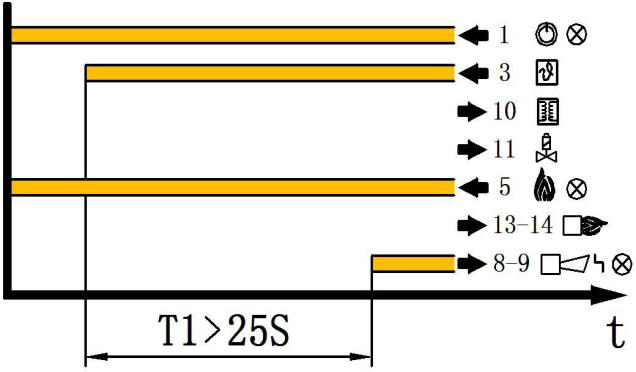

4.Start with a flame signal

There is a flame signal when starting ,FSC-1600 is waiting for T1 flame simulation test,the maximum waiting time is 25S, if T1 flame signal disappear in the flame simulation delay time,the burner will enter the normal start-up procedure, otherwise it will enter the fault-locked state,meanwhile the LED flashes to display fault code E1.

5.Self-locking or restarting after flame failure extinguishing

The controller has self-locking and restarting function after extinguishing,which decides whether the burner will lock or restart once again after flame failure extinguishing.

(1) Self-locking after flame failure extinguishing

A flame failure occurs during operation,the controller enters the fault-locked status in T3 and the gas valve closes at the same time,the fault signal output terminal 8 and 9 are closed,and the LED flashes to display fault code E3.

(2) Automatic restarting after the flame extinguishing

If the controller detects that the flame is extinguished after at least 2 seconds of normal operation, then the gas valve is closed during T3,at the same time the fire signal output is interrupted and the burner automatic restarts again for one time.If the burner fails to restart, it will enter the fault -locked state,LED flashes with fault code E2.If the controller detects a flame signal during T2,a fire signal is output,LED shows the current running status code x3,and the restart is completed.

6.Frequent opening and closing during T2.

If the start signal is turn on or off more than 3 times during the same start-up process,the controller enters the fault-locked state and at the same time LED flashes to display fault code E4.

7.The time between starting twice is too short

If it starts too often, the LED flashes to display fault code E7.

8.Continuous remote reset

The continuous remote reset signal input time received by the controller cannot be greater than T7,otherwise LED flashes with the fault code E6.The device maintains its original operating state and the fault is removed when the remote reset signal disappears.

9.Remote reset frequency is too high

If the remote reset operation frequency is too high,LED flashes with fault code E5.The controller enters a fault-locked state, This fault can be removed only by pressing the INFO/RESET button on the controller.

10.Failure type table

Code | The meaning of failure | Status | The method of removing failure |

E 1 | There is a flame signal at start-up | Stop | Remote reset or on site reset |

E 2 | Ignition failure | Stop | Remote reset or on site reset |

E 3 | Unexpected flameout | Stop | Remote reset or on site reset |

E 4 | 3 times opening and closing action within 15s of remote start signal | Stop | On site reset |

E 5 | 3 times opening and closing action within 10s of remote reset signal | Stop | automatically release without opening and closing action within 10s. |

E 6 | Remote reset signal is not restored | Continue operating | Remote reset canceled |

E 7 | Twice remote start signal times <10S | Stop | Disconnect remote wait and start |

E 8 | Internal error | Stop | Remote reset or on site reset |

E 9 | Internal error | Lock | Contact seller |

Cautions

Cautions

* Installers should have professional training and practical experience.

* Please check the installation level of the product to ensure that the product is suitable for installation.

* The power must be disconnected before installation ! Must be well grounded ! Otherwise it will cause personal injury and death or equipment damage !

* Full consideration must be given to protection against accidental electric shock and ensure that personnel do not come into contact with parts that are not fully insulated!

* Please read the installation instructions carefully before installation. If the operation is incorrect, it may cause damage to the product or cause an accident.