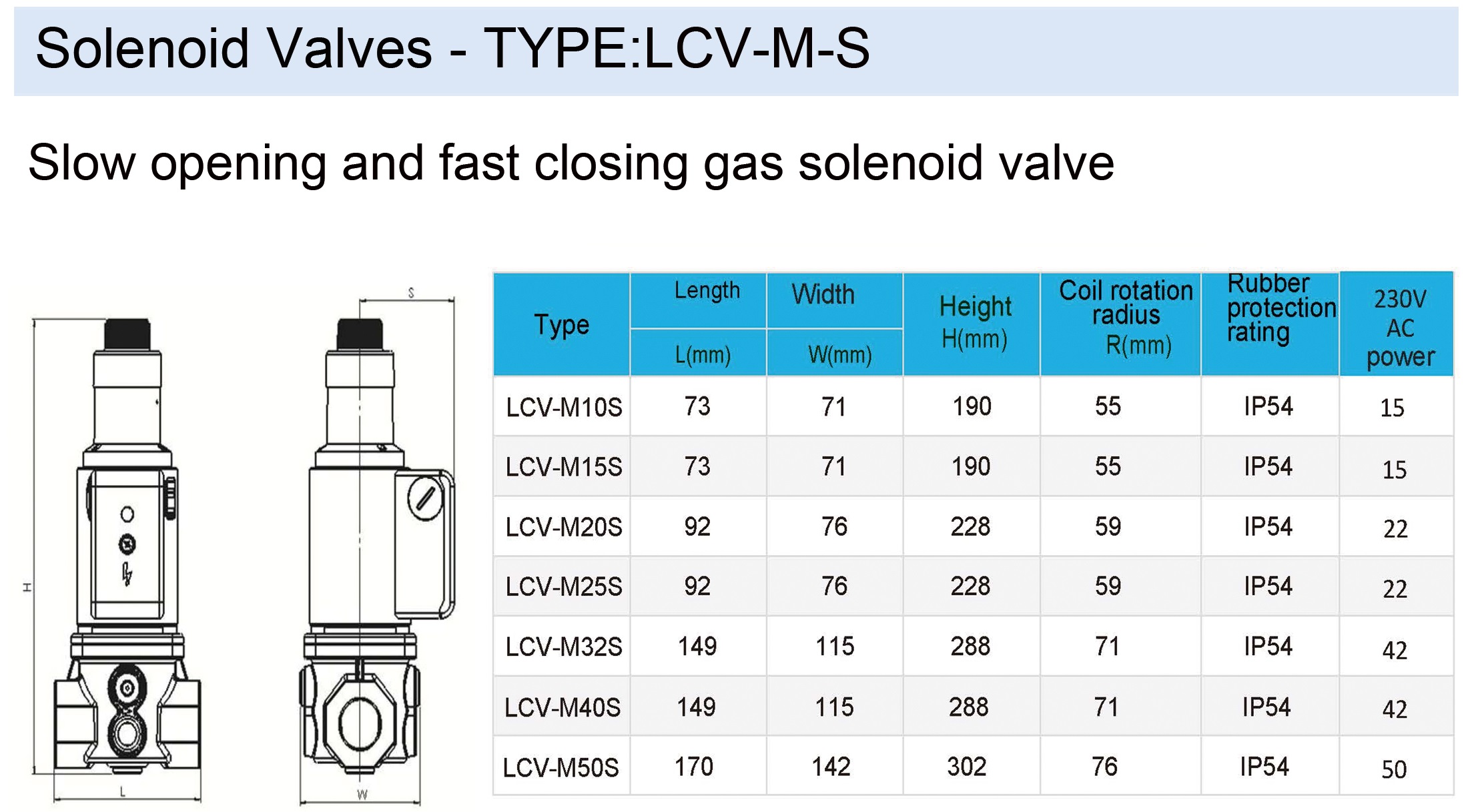

Slow opening and fast closing gas solenoid valve

Gas solenoid valve is also called gas emergency cut-off valve, it is applicable for a variety of gas such as city gas and natural gas.It is the actuator of two - position on - off switch and transmissioning automatic control for heating combustion medium pipeline.It is widely used in industrial furnace heating and gas heating automatic control systems in other industries.Also suitable for automatic gas supply of civil gas hot water boilers.

Product details

This gas solenoid valve can be widely used in the field of gas safety transmission control to provide gas supply for opening and closing or emergency cutting.

Can be applied to gaseous media such as natural gas,methane,liquefied petroleum gas,etc.

Features: adjustable opening time and adjustable flow.

Operation and installation

Normally closed, it will open quickly after power-on and the blue light is on.It will be closed immediately when the power is off and the light will be off .For the first time, you can re-adjust the factory setting mode state during power-on, adjust the opening time and adjust the size of the back-end output flow,as well as the fast-open or slow-open section within the open range.There are bypass holes on both sides or bottom of the valve body, and the hole diameter is G 1 / 4”

Standard and certification

“A”standard

Meets European gas standards

CE certification

Electrical specification

Rated voltage:50 / 60 Hz,230 Vac,110 Vac,24 VDC(and other specific)

Coil level F,can be 360° rotation,can work 100% continuously for a long time.

Gas solenoid valve installation and use precautions

1、When installing, it is advisable to select a horizontal pipe section with less vibration.90 degree installation is allowed below D50 and only horizontal installation is allowed above DN65.

2、The parameters on the solenoid valve label should match the actual use requirements.

3、The arrow on the solenoid valve body should be consistent with the flow direction of the medium.

4、To ensure the normal use of solenoid valve,please install a gas filter in front of the valve.

5、This valve is not explosion proof.

6、Thoroughly purge the pipe before installation to prevent foreign matter from damaging the diaphragm and causing the solenoid valve to malfunction.

7、If it is outdoors or in a bad environment,it should be correspondingly protected.

8、When the solenoid valve fails,it is recommended to install a bypass device for timely isolation and easy maintenance.

9、If the valve fails to open and close during using,check whether the coil is power off,whether power supply and medium pressure are normal.

10、When the solenoid valve is not installed, it can be stored in an indoor environment with a temperature of 0~40℃and a relative humidity ≤ 80 without corrosive gas.Open storage is not allowed.

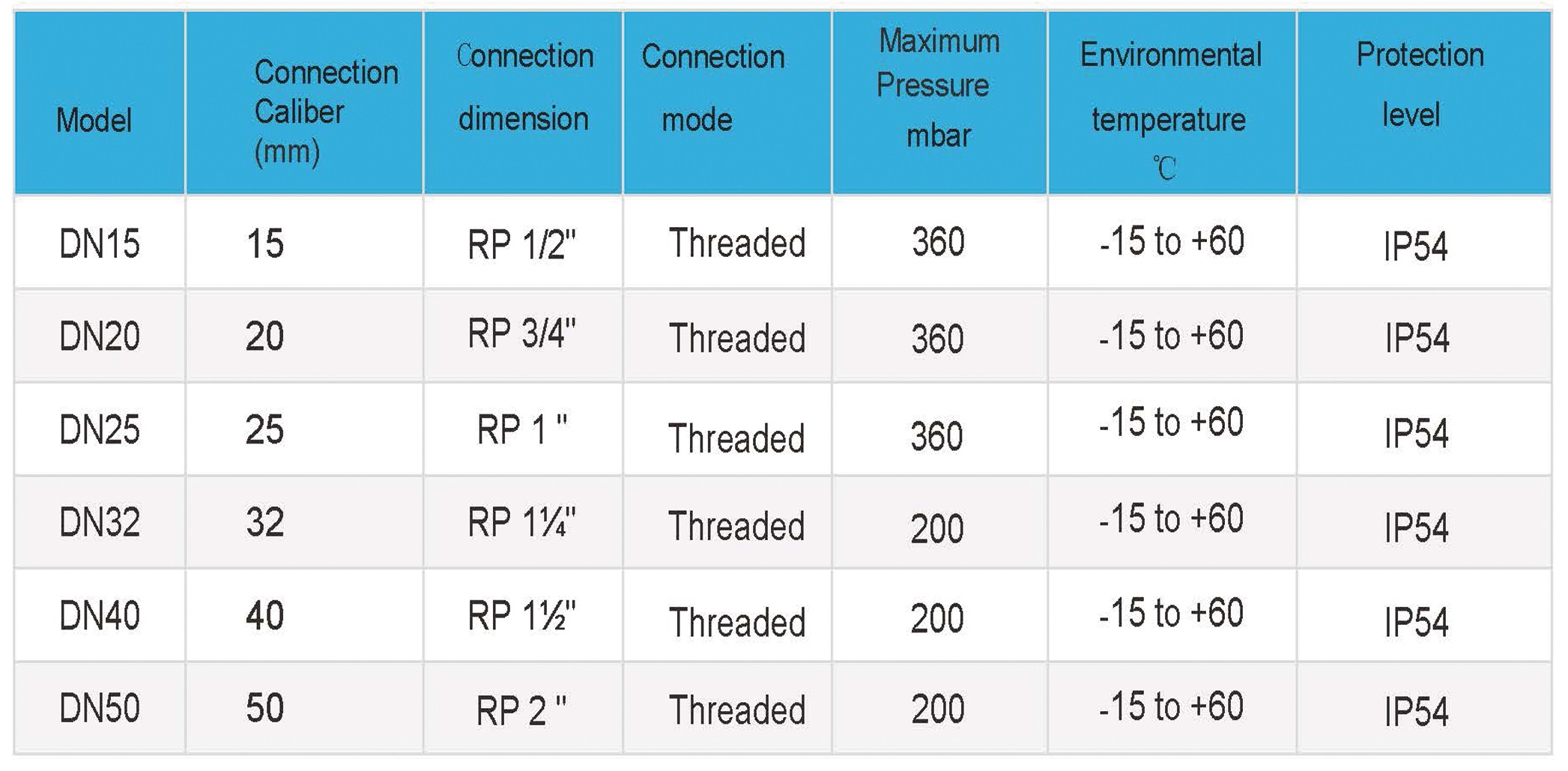

Technical parameter

Opening time 1-30 seconds adjustable

Closing time < 1 second

Maximum operating frequency:20 times/min

Maximum working pressure:

DN 10 - 25 360 mbar;DN 32 - 50 200 mbar

With G/4 aperture bypass hole

Built-in filtering

Protection level: IP54