Product Details

This kind of solenoid valve is adopted to add a regulate knob device on the basis of the fast-opening valve, and the gas flow size can be regulated by turning the knob when the valve is opened.

It can be applied to gaseous media such as natural gas, methane, liquefied petroleum gas, etc. There are bypass holes on both sides or bottom of the valve body, and its diameter is G1/4"

Introduction of the production

Fuel gas solenoid valves are widely applied to the safe transportation of fuel gases so as to start the supply of gases or cut it off upon emergency.

The mediums of gases applicable are: natural gases, methane, liquefied petroleum gas.

When activated, the blue indicator lights up, this allows the operators to check working mode through visual observation.

Operation and installation

Normally closed type, when the power is on, it will open quickly, and when the power is off, it will be shut down immediately.

By-pass ports are set on both sides and bottom of the valves, with diameter of G1/4” (DN10/15 diameter being G1/8”)

Flow can be regulated

Installation and use precautions

1. It is advisable to select a horizontal pipe section with less vibration when installing. Types with the diameter under DN50 (including DN50) allow maximum installation tilt angle of 90°; types with the diameter over DN65 only allow horizontal installation.

2. The parameters on the solenoid valve label should be consistent with the actual use requirements.

3. The arrow on the solenoid valve body should be consistent with the flow direction of the medium.

4. In order to ensure the normal use of the solenoid valve, please install a special gas filter in front of the valve.

5. The valve itself does not have explosion-proof performance.

6. Thoroughly purge the pipe before installation to prevent the foreign body from damaging the diaphragm and causing the solenoid valve to malfunction.

7. If it is installed outdoors and in harsh environments, it should be correspondingly effective protection.

8. When the solenoid valve fails, it is recommended to install a bypass device for timely isolation and easy maintenance.

9. If the valve fails to open and close during using, check whether the coil is powered off; whether the power supply and medium pressure are normal.

10. When the solenoid valve is not installed temporarily, it can be stored in indoor under 0-40℃ relative humidity of 80% or less. It is not allowed to be stored in the open air.

Technical parameters

Opening Time: less than 1 second

Closing Time: less than 1 second

Numbers of operations: 20 per minute.

Max working Pressure: 200/360mbar; DN32-50 200mbar

By-pass ports are set on both sides of the valves, with diameter of G1/4”

Built-in filtering

Protection: IP54

Sealing material: Nitrile rubber

Body material: aluminum alloy

Pressure steel spring AISI 302.

The ambient temperature: -15℃- 60℃

Coil temperature: 65℃

Standard and Certificate

Achieving Grade “A” standard

Meet standards EN161

Meet European Gas Standard, CE Certification Approved

Electrical specification

Rated Voltage: 50-60Hz, 230Vac、110Vac、24Vdc (other voltage can be customized).

Coils to Class F, can be 360° rotation, can work 100% continuously for a long time.

TYPE | Passage DN (mm) | Connection | Max Pressure (Mbar) | Operating temperature(℃) | Protection |

DN10 | 10 | RP 3/8" | 360 | -15 to 60 | IP54 |

DN15 | 15 | RP 1/2" | 360 | -15 to 60 | IP54 |

DN20 | 20 | RP 3/4″ | 360 | -15 to 60 | IP54 |

DN25 | 25 | RP 1″ | 360 | -15 to 60 | IP54 |

DN32 | 32 | RP 1¼″ | 200 | -15 to 60 | IP54 |

DN40 | 40 | RP 1½″ | 200 | -15 to 60 | IP54 |

DN50 | 50 | RP 2" | 200 | -15 to 60 | IP54 |

DN65 | 65 | PN16 | 200 | -15 to 60 | IP54 |

DN80 | 80 | PN16 | 200 | -15 to 60 | IP54 |

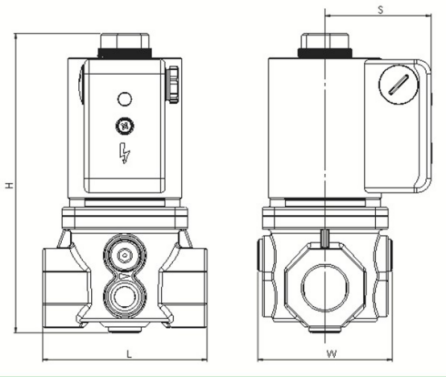

Type | Length L(mm) | Width W(mm) | Height H(mm) | coil gyration radius S(mm) |

LCV-RG10S | 73 | 71 | 125 | 55 |

LCV-RG15S | 73 | 71 | 125 | 55 |

LCV-RG20S | 92 | 76 | 167 | 59 |

LCV-RG25S | 92 | 76 | 167 | 59 |

LCV-RG32S | 149 | 115 | 236 | 71 |

LCV-RG40S | 149 | 115 | 236 | 71 |

LCV-RG50S | 170 | 142 | 252 | 76 |

LCV-RG65S | 310 | 185 | 302 | 85 |

LCV-RG80S | 310 | 200 | 331 | 85 |

Installation dimensions